THE EVOLUTION OF WINDOW CLEANING

We formed Presto Restoration Products, Inc. because we were dissatisfied with the products available to the building restoration and maintenance industry. Additionally, we wanted to simplify how businesses perform cutting-edge restoration and preservation services. We discovered that many of the products and techniques used by companies in the industry were outdated, and did not take advantage of the newest advances in chemical technologies. We also began to discover how many products and techniques actually caused problems through their use instead of solving them.

Initially, the use of ammonia to clean windows was common. Oily surfactants and ammonia helped lubricate the squeegee and prevent streaking. Eventually, building managers realized that ammonia was staining the exterior surfaces of the building, which are composed of materials such as limestone and precast. Next, the use of ordinary household dishwashing detergent became popular, and it continues to be used by most window cleaning companies today.

In professional high-rise window cleaning, this detergent is applied to the building’s glass with a mop and a squeegee. As a result, it runs onto window frames and other building surfaces, including precast and ledges. As the water evaporates, a dirty, soapy, oily mixture is left behind to attract additional environmental contaminates and cause ugly, hard-water stains.

Newer, safer window cleaning detergents have been developed as a result of a “Green Frenzy” that puts environmental and employee safety as the number one concern. Dishwashing detergents are designed to aggressively fight grease and oils commonly found in cooking applications. These products are meant to be used with protective gloves. Within the professional high-rise maintenance industry, most window cleaning professionals do not wear gloves since it tends to hinder their ability to do the job.

Glass Restoration

View Before & After Photos

Photos of glass stains on commercial multi-story buildings

WHERE DO GLASS STAINS COME FROM?

This is a common question for property owners, managers, contractors and suppliers all over the world. Many factors can cause glass stains. Every building is exposed to a distinct combination of elements for differing lengths of time, resulting in varying types and levels of staining on its surfaces. Some of the factors that contribute to glass staining are as follows:

- Buildup of surfactants (soap scum) and oils from sticky window cleaning detergents that attract dust and dirt

- Use of high mineral content tap water during window cleaning

- Water erosion carries minerals from adjacent concrete or precast surfaces

- Contact with high mineral content water through sprinkler systems

- Over spray from careless waterproofing and painting projects

- Leaching of deteriorating caulking or coatings

- Leaching of contaminates from adjacent rusting metals

- Leaching of failed UV-sensitive, water-repellent performance

- Atmospheric pollutants including acid rain, dust or other man-made environmental pollution

After more than a decade of research and product development, Presto Restoration Products, Inc. has worked through every possible cause of glass staining and has created a complete line of products to not only attack the problem, but prevent it from reoccurring.

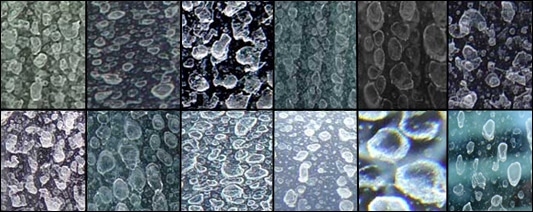

Below are 12 pictures of different examples of glass stains that Presto has removed using its own line of products.

GLASS REPLACEMENT VERSUS GLASS RESTORATION

Proper glass restoration can be an expensive investment, but one that should not be disregarded or postponed. The longer glass containing stains is subjected to the cause of the problem, the higher the cost to repair the problem. Replacing windows is an even more costly alternative. The cost to replace most exterior windows is anywhere between $350 and $8,000 per window. Restoring these same windows is roughly $5 to $20 per window in product costs.

WHY MOST GLASS RESTORATION PRODUCTS AND METHODS DON’T WORK

Many companies solve glass staining problems by using abrasive techniques that scratch the glass and/or harsh acid products that leave burns on the glass and surrounding surfaces creating a hazed look (see image below).

Acidic products that have hydrofluoric acid can be harmful to both employees and structures since they are normally washed down the sides of the building, damaging window frames and precast surfaces. After over a decade of research, Presto has developed methods that use no harsh abrasives or acids yet still leave glass distortion-free.

Click to view more pictures of window glass damage

RESTORE, PROTECT, MAINTAIN

| It is critical to select the right combination of products to protect the environment and maintain the exterior beauty of high rise properties. Presto has designed its products to work synergistically – not against one another. Follow Presto’s three-step process to restore, protect and maintain the glass on any high-rise building: RESTORATION Glass ReSurfacer® Final Polish: Effectively removes flaws from architectural glass surfaces, producing a scratch-free and highly reflective finish on the glass surface Glass ReSurfacer® Stripper: Used to remove heavy mineral staining prior to the Glass ReSurfacer Final Polish. This product is acid-based formula that should only be used when absolutely necessary. EnviRestore® Glass Stain Remover: A restorative cream that removes stubborn stains from glass surfaces without the use of machinery PROTECTION Glass Defender® Series (HD, MD): Invisible protection that fills in porous glass surfaces forming a hard coating that won’t fade, crack or peel; protects glass from damaging elements and prevents scratching for up to 10 years | Presto’s Glass ReSurfacer® System uses no harsh abrasives or acids, completely removing stains from the glass without leaving any scratches or burns, yet still leaving the glass highly polished and distortion-free Presto’s Glass Defender HD applied to a glass surface protects the glass, forcing water to bead up and run off the surface. |

PRESTO’S RECOMMENDED MAINTENANCE SCHEDULE

It is essential that a strict maintenance schedule be kept after restoration is complete to ensure that your property remains stain-free.

- Clean windows two to three times annually with deionized water.

- Protect the glass using Presto’s Glass Defender Series every 10 to 20 years.

- Seal the precast using Presto’s Leach Stop® Mineral Leaching Mitigation Treatment™ every 5 to 15 years as needed. This will prevent stains caused by materials leaching out of the precast and onto the glass.